Manufacturing Model

This document is a technical reference item for administrators and programmers, that describes how the data model of the ofbiz manufacturing application works.

Terminology

Manufacturing Tasks:

- A production run is a series of tasks which converts raw materials to finished products.

- A production run task is a particular task of the production run.

- A routing is a template of tasks to be performed to produce a product.

- A routing task is one particular task in the routing.

Data Model Usage

Only a few entities are used to do everything in manufacturing. Different type keys (workEffortTypeId, workEffortAssocTypeId, workEffortGoodStdTypeId) are used to make the same entities perform different roles. I will not re-type all the keys here. Run a few production runs and take a look at what data is in the entity model, and this will make more sense. The following entities are used by the manufacturing application:

- WorkEffort (WE): All manufacturing tasks are modeled as WorkEffort with different workEffortTypeId's. The workEffortParentId is used to associate production run tasks to the parent production task. Descriptive information, times, and dates are all stored on WorkEffort.

- WorkEffortAssoc (WEA): Routing tasks are associated to routing via WEA. When a production run is created, production run tasks are associated to routing task via WEA.

- WorkEffortGoodStandard (WEGS) is used to do three things:

- Record which routing (template) is used to produce a product

- Record which products are needed for a particular production run task

- Record which product is actually produced by a production run

- Record which product is used to define the purchasing of outsourcing for a routing task (in opentaps Warehouse application.)

- WorkEffortInventoryAssign (WEIA) is used to record actual inventory items issued to a production run task.

- WorkEffortInventoryProduced (WEIP) is used to record actual inventory items produced by a production run.

- WorkRequirementFulfillment (WRP) records how Requirements are fulfilled by actual production runs.

- WorkEffortFixedAssetStd (WEFAS) may be used to set the fixed asset for a routing and tasks

- WorkEffortFixedAssetAssign (WEFAA) may be used to set the fixed asset for actual production run and tasks

MRP runs off the MrpInventoryEventPlanned, which is a chronological set of entries about when production runs, purchase orders, and so on are taking place. A "+" indicates an event which increases inventory, a "-" one which decreases it.

The TechDataCalendar entity is used to configure the manufacturing calendar and determine how many calendar days a production run might take based on the run time set in milliseconds.

Following the Inventory

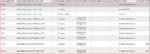

Inventory is issued to the production run steps through WEIA and then produced out of the production run header in WEIP. The production run steps are linked to the production run header in the main WE entity. See the following screenshots for examples, where MAT_A_COST and MAT_B_COST are used to manufacture PROD_COST.

Example Manufacturing Scenario with User Guide Links < Manual Pages

What the Production Management Processes Do < Section Pages > Product Manufacturing Structures